xBT Temperature Sensing Chip

- 134kHz FDX-B Bio-Thermo LifeChip

- 2.4×14.5mm cylindrical biocompatible implant package with anti-migration cap

- Want an analog? Check out the STL

More Details X-Series FAQ Partner Map

THIS PRODUCT IS BEING DISCONTINUED; WE WILL NO LONGER RE-STOCK

$99.00

More Details

WARNING This kit definitely contains dangerous things. While the xBT (LifeChip) transponder device has undergone several quality checks during manufacture and has been put through a battery of tests with various private labs, it has not been tested or certified by any regulatory agency for implantation or use inside the human body. Use of this device is strictly at your own risk.

The xBT kit contains the xBT chip and all the sterile procedure materials required to perform installation. The xBT chip is made with 134kHz FDX-B compliant Bio-Thermo LifeChip, which is encased in biologically safe 2.4×14.5mm cylindrical borosilicate bioglass tube and shipped in a sterilized injection assembly. The xBT reports a simple ID number which works with any FDX-B reader, and can also transmit temperature sensor data to a compatible Bio-Thermo reader.

The xBT chip is not an NFC device!

To read the xBT chip and get temperature data, we suggest using the Halo scanner from Micro-ID.

To read the xBT chip and get temperature data, we suggest using the Halo scanner from Micro-ID.

xBT Kit Contents

- 1 sterile injector assembly, pre-loaded with an xBT chip

- 2 single use ChloraPrep antiseptic wipes

- 1 sterile gauze pad for post-injection wound care

- 1 sterile expandable-fabric adhesive bandage

- 1 pair of non-sterile, non-latex procedure gloves

Passive RFID and NFC chips are magnetically coupled devices that power themselves and communicate data over a shared magnetic field the reader generates. This means their effective read range and performance depends entirely on how well the antenna coils of both the tag and reader couple with each other. This typically means the shape, size, and orientation of both antennas must be complimentary.

Passive RFID and NFC chips are magnetically coupled devices that power themselves and communicate data over a shared magnetic field the reader generates. This means their effective read range and performance depends entirely on how well the antenna coils of both the tag and reader couple with each other. This typically means the shape, size, and orientation of both antennas must be complimentary.

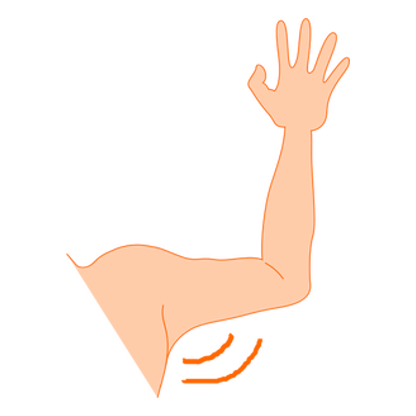

Typically, our x-series transponders are installed into the webbing between the metacarpal bones of the index finger and thumb, resting parallel to the index metacarpal. However, the xBT’s thermal sensor provides the most stable output when installed away from extremities and closer to the core of the body. Temperature in the hands and arms can fluctuate rapidly with changes in surrounding ambient temperature, and are not ideal for recording stable thermal readings.

Typically, our x-series transponders are installed into the webbing between the metacarpal bones of the index finger and thumb, resting parallel to the index metacarpal. However, the xBT’s thermal sensor provides the most stable output when installed away from extremities and closer to the core of the body. Temperature in the hands and arms can fluctuate rapidly with changes in surrounding ambient temperature, and are not ideal for recording stable thermal readings.

BioBond is a porous material that, when applied to the bioglass encasement of the chip, forms an “anti-migration cap” which promotes tissue growth throughout its porous structure. The goal is to secure the tag and stop it migrating by literally letting the body grow into it to hold the chip in place.

BioBond is a porous material that, when applied to the bioglass encasement of the chip, forms an “anti-migration cap” which promotes tissue growth throughout its porous structure. The goal is to secure the tag and stop it migrating by literally letting the body grow into it to hold the chip in place.